RTLS solutions in warehouse and supply chain

The logistics and supply chain industry is growing increasingly complex, and Real-Time Location Systems (RTLS) have emerged as a popular engineering solution for intralogistics operations. The efficient tracking of inventory management and operational processes, especially in dynamic environments like ports and warehouses, has become a technical challenge of our time.

Logistic processes in ports play a crucial role in global trade. Nowadays, RTLS technologies are becoming a strategic tool to enhance operational efficiency. RTLS can help track containers in real-time, optimize inventory levels, and provide detailed operational analysis. This leads to tangible solutions for improving logistics efficiency. Engineers consider the integration of RTLS into the logistics industry as a technological necessity.

Implementing RTLS technology in warehouse and logistics sectors has made a significant contribution to the business world. It offers real-time visibility, automation, and optimization in critical areas such as asset tracking, supply chain management, employee safety, and customer experience. Companies that have adopted and integrated RTLS into their operations benefit from increased efficiency, reduced costs, and improved productivity.

General Operating Principles of RTLS and Market Growth Forecast

RTLS technology is a highly effective method of managing and analyzing workplace safety and efficiency in complex logistics processes, particularly in warehouses and ports. Essentially, RTLS uses tags or sensors embedded in a network to determine the real-time location of assets. These tags utilize technologies like UWB, BT, or Wi-Fi for indoor spaces and GPS, UWB, and other such technologies for larger outdoor areas. The tags send the location information of all assets, including personnel and equipment, to a central database. (For more info on RTLS, please see our article.)

Based on previous analyses, the Real-Time Location Systems (RTLS) market is predicted to experience a growth rate of nearly 24% in the next decade across various sectors, including the logistics industry. The market value is expected to reach approximately 37 billion dollars by 2032.

Main question: Why?

The Impact of RTLS Solutions on Logistics Performance

The increasing demand for RTLS technology in warehouse and logistics operations can be attributed to its smart and traceable nature. This technology reduces human errors, saves costs, increases productivity, and optimizes staff utilization. Real-time tracking of containers and pallets, improved inventory management, and faster operations provide significant benefits to logistics managers. Additionally, RTLS's precise position tracking capabilities minimize collisions and improve worker safety in high-traffic and mobile equipment environments. This system makes operations more organized and efficient.

Inventory Management and Warehouse Analytics with RTLS

RTLS technology plays a crucial role in inventory management and supply chain operations in the industry. It enhances efficiency and ensures workplace safety. The integration of RTLS with a variety of systems in warehouses enables holistic and applicable analyses while maximizing resource utilization. Making every stage of operational processes traceable and visible, examining and optimizing flow analyses through user-friendly RTLS software platforms provide companies with benefits such as improved customer satisfaction and a competitive edge. This approach also offers significant advantages in optimizing inventory management, reducing error rates, and enhancing overall operational efficiency.

Real-Time Location System (RTLS) optimizes inventory management by allowing products to be tracked in real-time within the warehouse. This ensures that stock levels are accurate and up-to-date.

2. Reduction of Error Rates

The precise location determination features of RTLS assist in minimizing manual interventions and human errors. It prevents errors such as incorrect placement or loss of inventory.

3. Increase in Operational Efficiency

Real-time tracking of inventory through RTLS enables more effective management of operational processes. Material movement and logistics operations become more organized, which contributes to increased efficiency.

4. Supply Chain Transparency

RTLS provides greater transparency by tracking all stages of the supply chain in real-time. Every step in the supply chain can be monitored in real-time, resulting in greater visibility and transparency.

5. Cost Reduction in Inventory Management

Calculated inventory and low error rates result in a decrease in inventory costs. It also contributes positively to the budget by preventing material loss, which can otherwise be a significant cost.

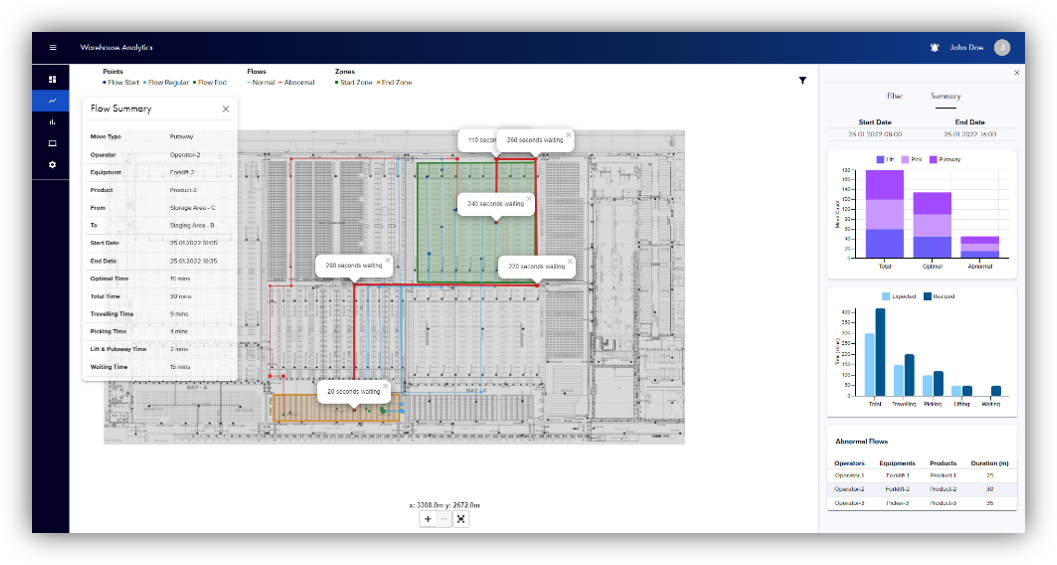

Optimized Operational Processes with Flow Analytics

The lack of visibility and traceability can lead to unpredictable operational inefficiencies and an increased need for employee safety in intralogistics operations. The use of RTLS technology with UWB infrastructure can help track the performance of assets with high-precision location information. By utilizing dynamic heat maps and footprints, it can consolidate missing pieces in the data chain. This enables the visualization of tasks and processes, such as abnormal flow analysis, flow optimization, workload prediction, and workforce optimization, through flow analytics software, thereby managing all logistics operations on a single platform.

RTLS technologies have made it easier to integrate and distribute tasks with the help of AI, and to match RTLS data with WMS for visualization purposes.

RTLS combined with AI for warehouse and supply-chain management

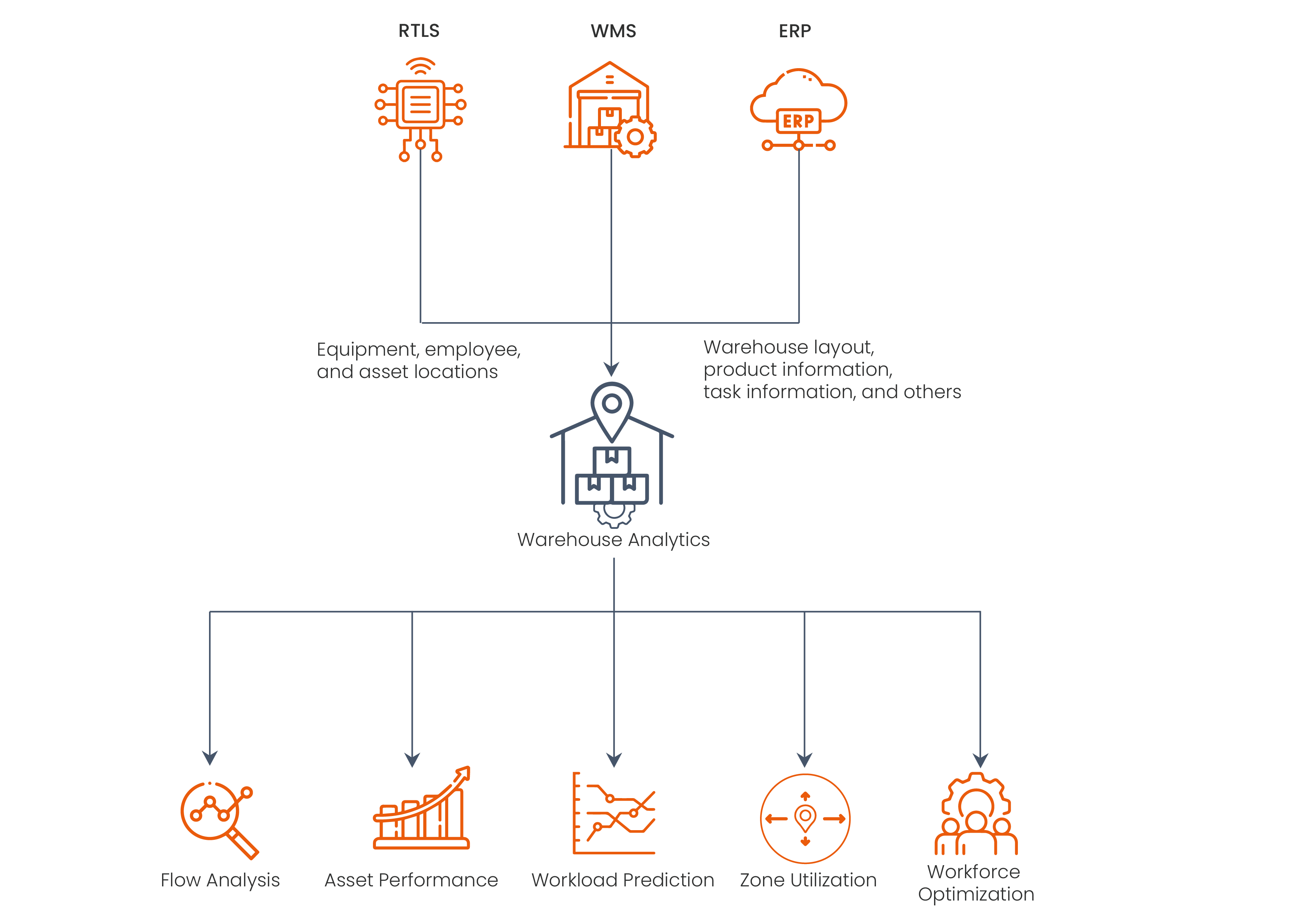

Nowadays, warehouse and supply chain management has become a complex and fast-paced field that keeps evolving. As a result, businesses need to manage and analyze real-time data coming from different systems effectively. To achieve this, the integration of RTLS based artificial intelligence technology has started playing a significant role in enhancing warehouse operations and better managing processes. With the help of AI, warehouse and supply chain management has become faster, more efficient, and predictable, leading to an overall improvement in the operational environment.

Let's take a moment to review the advantages of RTLS-based artificial intelligence;

- Data Integration and Analysis: Real-time data is collected from various systems, such as WMS and ERP, and analyzed holistically in the warehouse analytics platform.

- Holistic Analysis with Artificial Intelligence Algorithms: The application of AI algorithms allows for visual analysis of data through historical and real-time spaghetti diagrams.

- Equipment and Area Utilization Reports: The use of AI generates reports and recommendations for optimizing equipment and area utilization, improving operational efficiency.

- Performance Indicators Tailored to Various Roles and Responsibilities: Displaying accurate key performance indicators for each role is essential in assessing individual performance.

- Workload Prediction and Determining Optimal Equipment/Personnel: Artificial intelligence can anticipate workload for operations and suggest optimal strategies for equipment and personnel allocation to achieve best results.

At Wipelot, we offer assistance in propelling your logistics operations towards digital transformation. We provide custom solutions tailored to meet your facility's needs, ultimately making your operations more efficient and boosting productivity in your business processes.